Alliance Organics LLP is a Large Scale Manufacturer of Reactive Dyes at their plant in VAPI. Our Plant is ZDHC Level 3 Certified and our Reactive Dyes are GOTS version 6 and Eco Passport Certified

Allozol SD Dyestuffs or Reactive ED Dyes or Polyfunctional Reactive Dyestuffs

Allozol SD Dyes are Long Chain Reaction Molecules.

Allozol SD Dyes are suitable for dark shades having high strength, good built up properties, economical, suitable for various dyeing.

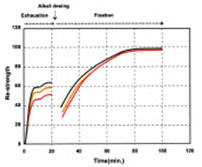

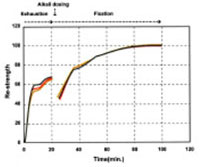

Dyeing Process of SD Dyestuffs

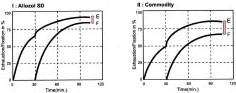

RFT (Right First Time) Dyeing

Excellent lab to bulk and bulk to bulk reproductibility with low sensitivity under varius dying parameters.

Commodity

G. Yellow MER

1.170%

RED ME4B

1.170%

NAVY BLUE BF

0.625%

ALLOZOL SD

G. YELLOW SD

0.80%

RED SD-3B

0.80%

NAVY BLUE SD

0.40%

Dyeing condition of standard

Fabric

:CM 40's cotton 100%

Migration Time

:20min

Temp. x Time

:60℃ x 60min.

Liquor ratio

:1:10

Gluaber's salt

:45g/l

Soda ash

:15g/l

Commodity

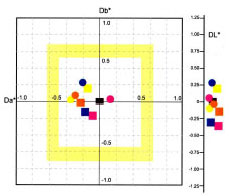

ALLOZOL SD

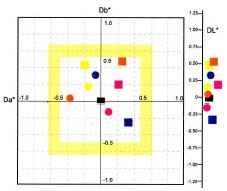

Commodity

ALLOZOL SD

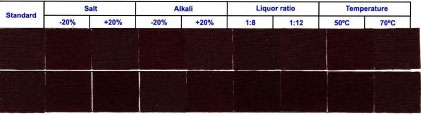

Standard

Salt - 20%

Salt + 20%

Alkali - 20%

Alkali + 20%

Liqucr ratio - 1:8

Liqucr ratio - 1:12

Dyeing Temp. 50℃

Dyeing Temp. 70℃

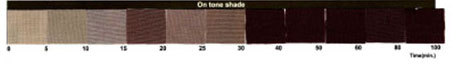

ON - TONE SHADE COMPATIBILITY STUDY TO GET COMPARATIVE VERY GOOD

ON TONE DEVELOPMENT

Commodity

G. Yellow MER

1.4%

RED ME4B

1.4%

NAVY BLUE BF

0.2%

ALLOZOL SD

G. YELLOW SD

0.8%

RED SD-3B

0.8%

NAVY BLUE SD

0.6%

COMMODITY

ALLOZOL SD

Commodity

ALLOZOL SD

The contented infomation and recommendation presented here were carried out with the utmost care, but cannot be extended to cover every possible case. They are intended to server as reference and must be adapted to the prevalling condition but any conclusions and recommendations made are without liability on our parts. Buyers and users should make their own assessment of our products under their own condition and for their own requiements.

ALLOZOL SD SERIES FOR DEEP TO INTENSIVE SHADES

- ALLOZOL G. YELLOW SD

- ALLOFIX G. YELLOW MER

- ALLOZOL RED SD-3B

- ALLOFIX RED ME4B

- ALLOZOL NAVY BLUE SD

- ALLOZOL NAVY BLUE BF

The unique properties of the ALLOZOL SD series reactive dyes lead to a significantly reduced impact in the wastewater and in the total environment costs.

Reduced production costs |

Total dyeing depath |

Glauber's salt | |||

|---|---|---|---|---|---|

| I |

G. YELLOW SD RED SD-3B NAVY BLUE SD |

→ 1.6% → 1.6% → 1.2% |

→ 4.4% |

65 gms./L |

|

| II |

G. YELLOW MER RED ME4B NAVY BLUE BF |

→ 2.8% → 2.8% → 1.5% |

→ 7.1% |

85 gms./L |

|

Excellent wash-off property

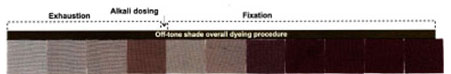

ALLOZOL SD approximately 85 - 90% of the dye applied to cotton is fixed, as compared 70% with normal commodity reactive dyes.

E : Exhausition

Part of used dyestuff that is either fixed or unfixed on the cellulose-fiber at the end of the dyeing cycle.

F : Fixation

Part of used dyestuff that is fixed on the cellulose-fiber at the end of the dyeing cycle.

S : Substantivity

Part of used dyestuff that gets absorbed by the cellulose-fiber during the salt phase.

Wash-off property

- 1

- 2

- 3

- 4

- 5

Test Method

1) Cold water 30℃ x 5 min

2) Hot water 80℃ x 5 min

3) Soaping 90℃ x 5 min

4) Hot water 80℃ x 5 min

5) Hot water 30℃ x 5 min

| Reactive ‘SD’ Dyes | Shade |

|

|

|||||||||||||||||||

|

|

|

||||||||||||||||||||

|

|

|

||||||||||||||||||||

|

|

|

||||||||||||||||||||

|

|

|

||||||||||||||||||||

|

|

|

||||||||||||||||||||

|

|

|

||||||||||||||||||||

|

|

|

||||||||||||||||||||

|

|

|

||||||||||||||||||||

|

|

|

||||||||||||||||||||

|

|

|

||||||||||||||||||||

Recommended Trichromy for Reactive SD Dyes

| DARK SHADE |

|---|

| Allozol G. Yellow SD |

| Allozol Red SD-3B |

| Allozol Navy Blue SD |